UP3D P55D Dry Milling Machine

Technical and Performance Specifications

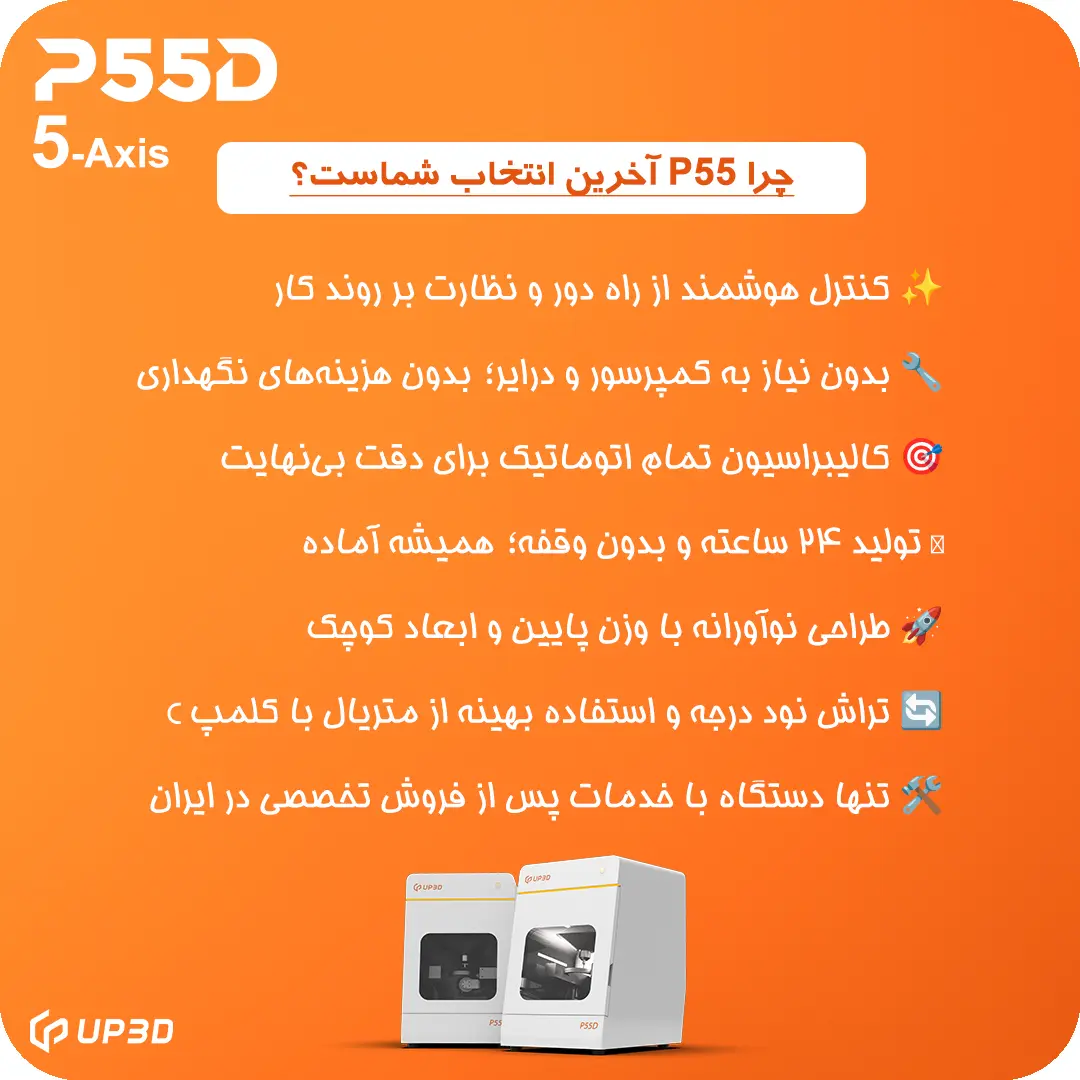

- Innovative 5-Axis with Advanced Technology for Enhanced Precision

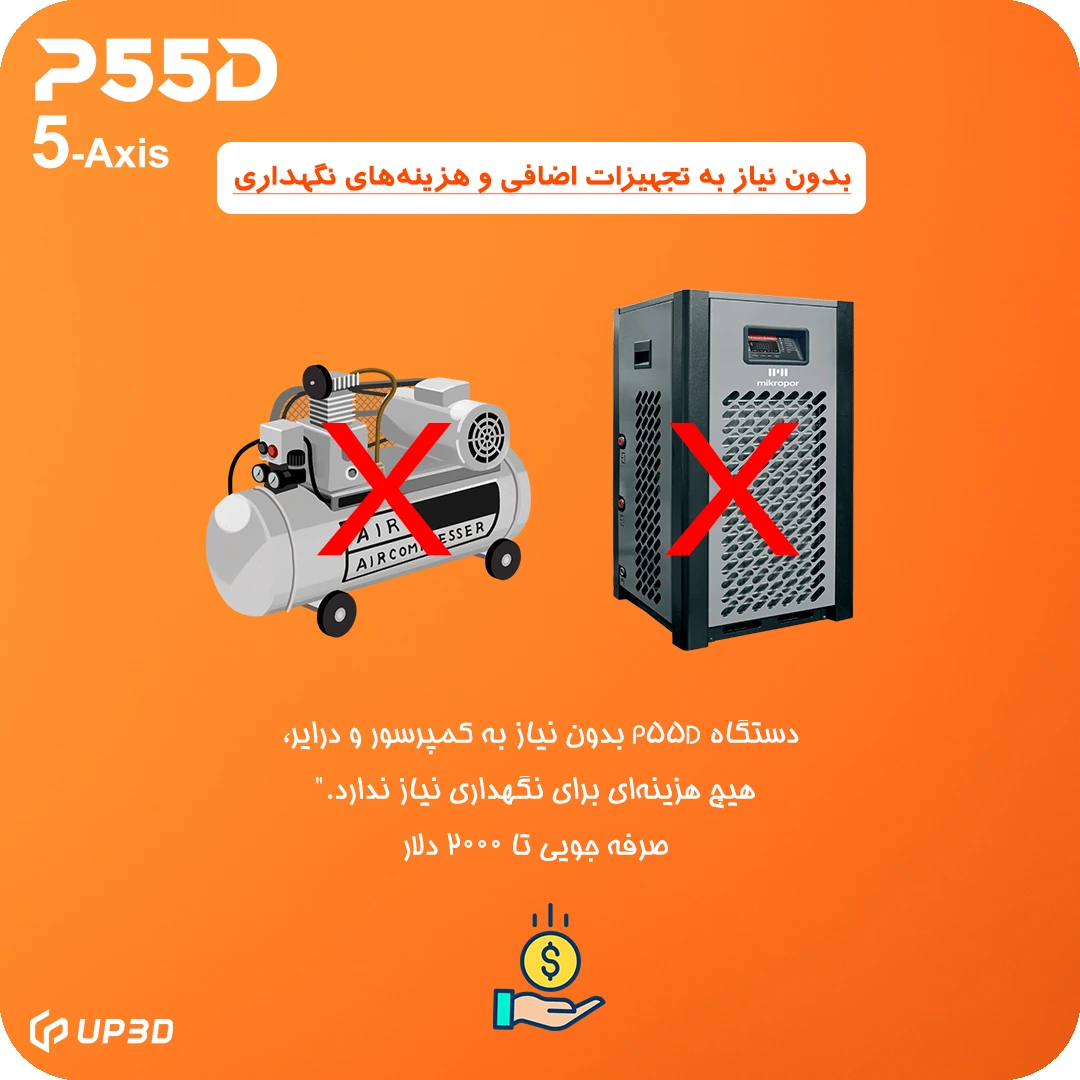

- Dry Milling Without the Need for an Air Compressor

- Fully Automatic Calibration with High Precision

- Dual Electric and Mechanical Sensor System for Enhanced Milling Accuracy

- Real-Time Milling Process Progress Display

- Powerful 600W Spindle for Fast Milling of Hard Materials

- 15-Tool Magazine with High Flexibility in Tool Selection

- Advanced Servo Motors for Continuous 24/7 Operation Without Interruption

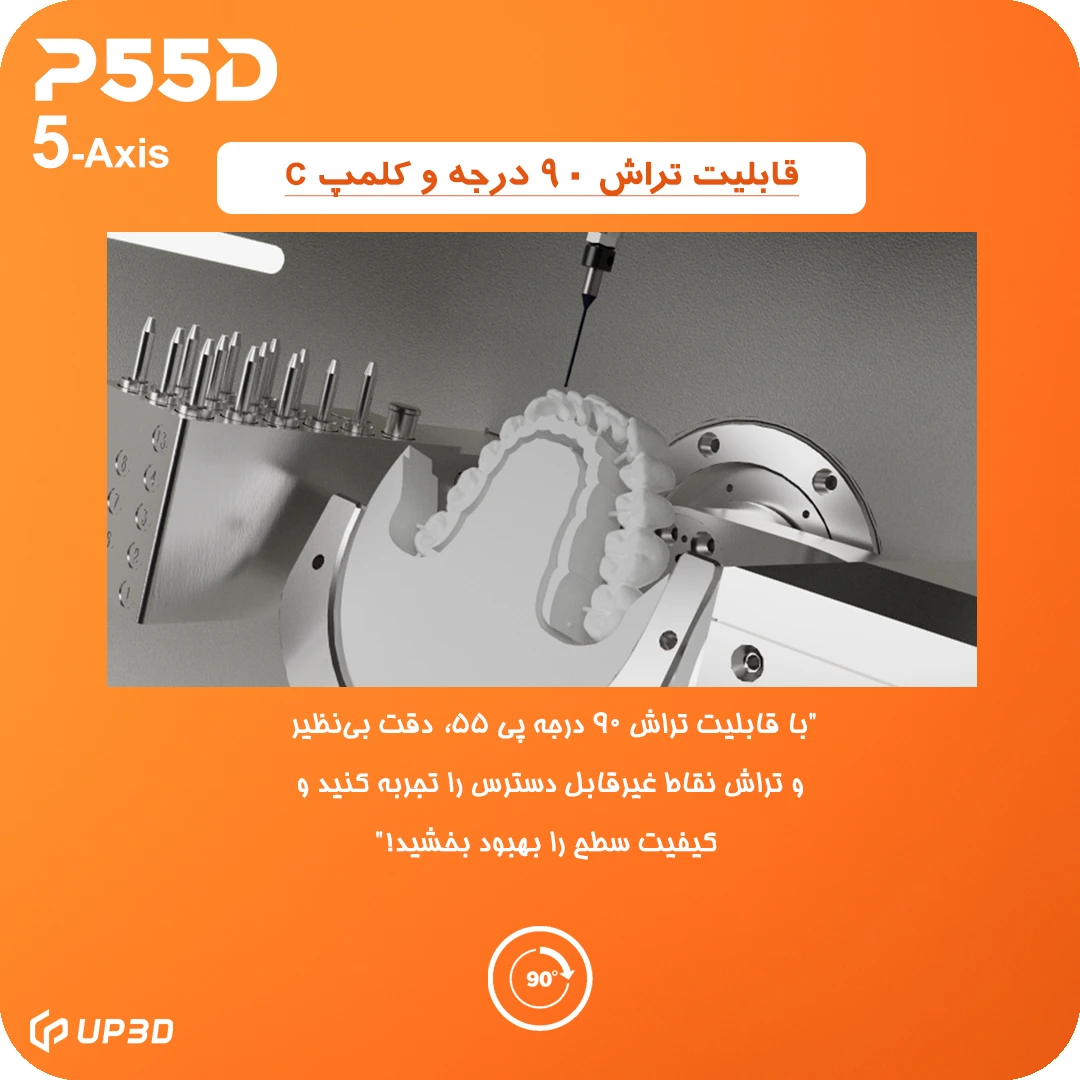

- 90-Degree Milling Capability for Precise Proximal Milling in Sensitive Areas

- Intelligent Diagnostic Technology for Automatic Problem Detection and Rapid Troubleshooting

All these features make the UP3D P55D milling machine an ideal choice for digital dental laboratories.

1.750.000.000تومان

Introduction to UP3D P55D Milling Machine

The UP3D P55D milling machine from UP3D (UpTrade) is an advanced flagship dry milling device in the digital CAD/CAM field. Featuring precise servo control technology and stable performance under all conditions, it enables continuous and accurate machining for 24 hours without requiring an air source. Its plug-and-play design and powerful German spindle make operation easy and fast. With the intelligent MillMind software, remote control of the machine is also possible. This device is compatible with a wide range of materials including zirconia, wax, PMMA, PEEK, and soft metals.Key Features of the P55D Milling Machine

- Precise and Stable Servo Control The full servo drive system compensates for milling vibrations, ensuring precise 24-hour continuous production.

- Airless Spindle (No Compressor Required) German motor with a speed of 60,000 RPM and an airless design ensures easy installation and reliable performance.

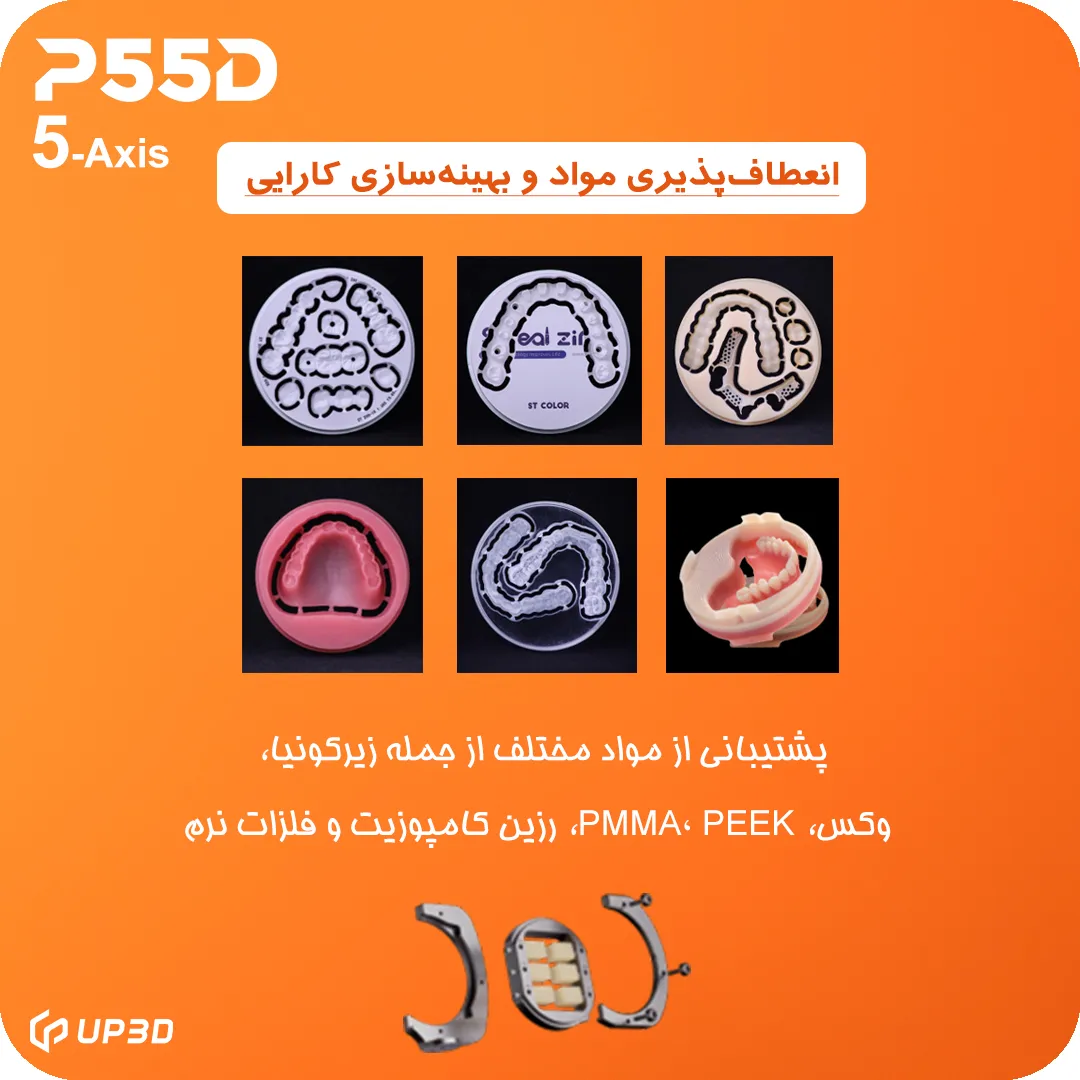

- Compatibility with Various Materials: From zirconia to soft metals, this machine is compatible with various discs and blocks.

- Smart Remote Control: MillMind software enables full control, alerts, and device status monitoring.

- Dust-Resistant Design: The silicone-insulated body prevents dust ingress and reduces maintenance needs.

- Easy and Low-Cost Maintenance: The machine's modular structure allows users to perform repairs without specialized technical experience.

- Larger Milling Chamber: Increased workspace enhances speed and ease of operation.

- Intelligent Automatic Calibration: Without manual intervention, the machine calibrates itself accurately and automatically.

ZIG – Official Representative of UP3D in Iran

ZIG, as the official representative of UP3D in Iran, offers this machine with full installation, training, expert consultation, and technical support services. To compare this product with other milling machines, you can visit the ZIG Tech section. Visit or contact the ZIG team for a complete introduction to the UP3D P55D milling machine and to receive expert consultation.P55D

Power Inside, Simplicity in Use

Fully intelligent design without the need for an air compressor (Plug & Play)

Flawless precision for all dental materials — beautiful and reliable results with every milling.

High-quality spindle for continuous zirconia milling

The P55D is designed for continuous milling of zirconia crowns with exceptional precision and durable bearings. Its German spindle spins up to 60,000 RPM, and the noise- and vibration-resistant structure ensures stable, efficient, and quiet operation across all speeds. Experience professional and unmatched milling with the P55D—ideal for maximizing productivity.

Intelligent Servo System

Ultra-precise milling

The P55D’s intelligent servo system actively reduces vibrations during crown milling, delivering micron-level precision with exceptional stability. Its advanced drive and servo system provide high torque and seamless motor-controller integration. Designed to meet the demands of the most complex restorations, this smart system offers reliable, high-quality results with minimal manual adjustments, instilling confidence in every case.

User-friendly with quick and easy learning curve

No compressed air required

Without the need for compressed air, the P55D offers a Plug & Mill system setup. This integrated, accessory-free design enables easy installation and high efficiency. Eliminating compressors and dryers reduces maintenance costs and keeps the machine ready for operation at all times.

One click to start milling

After powering on, the P55D automatically completes all startup and CNC setup processes. Simply send the design file and start milling with one click—everything happens within seconds, with no complex configurations needed.

Control your milling machine anywhere wit MillMind

With the MillMind cloud service, you can easily manage UP3D milling machines via your smartphone or tablet. Monitor machine status in real-time, receive intelligent milling alerts, and track tool life to minimize downtime and maximize production efficiency.

With MillMind, stay connected to your lab’s workflow anytime, anywhere, ensuring smooth and uninterrupted operations.

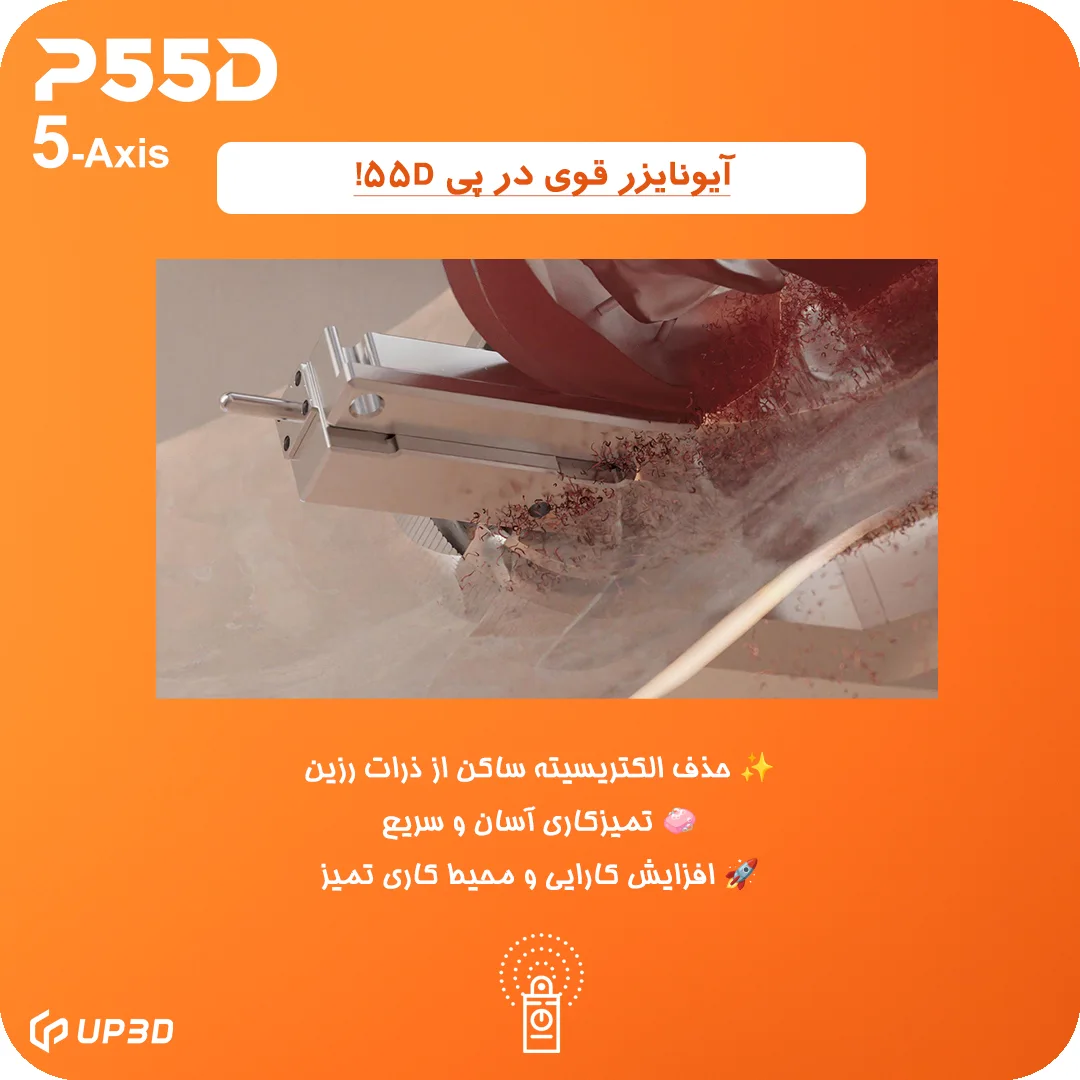

Powerful Ionizer for Resin Powder Removal

The P55D is equipped with a high-focus ionizer that neutralizes the electrostatic charge of resin powders like PMMA, making the cleaning process faster, more effective, and easier. Additionally, by eliminating the need for expensive accessories such as compressed air tools, initial and maintenance costs are significantly reduced.

UPCNC For UP3D milling machines

With UPCNC, take full control of your UP3D milling machine. Easily monitor tool usage, receive instant job completion notifications, and get alerts for any errors—ensuring optimized production scheduling and uninterrupted workflow.

The intuitive and user-friendly UPCNC interface simplifies machine operation, allowing you to focus on what matters most.

UPCAM Intelligent Dental Nesting Software

Seamless Integration | Easy to Use

- Automatic Nesting

- Comprehensive Solution

- Toolpath Simulation

| Device dimensions | 655 × 442 × 704 millimeters |

|---|---|

| Weight | 98 kg |

| Number of axes | 5 axes (A: ±360° / B: ±30°) |

| Milling type | Dry milling |

| Spindle speed | Up to 100,000 RPM |

| Spindle power | 860 watts (high frequency) |

| Number of tools | 13 tools with automatic changer + intelligent monitoring |

| Suction system | M-level filter / air pressure 2500 liters per minute |

| Supported materials | Zirconia, wax, PMMA, PEEK, composite resin, soft cobalt-chromium |

| CAM software | UPCAM |

⏳ Please wait a moment, the 3D model is loading...

Click here to view the product on the official UP3D website:

View on UP3D website🎥 Introduction Videos of the UP3D P55D Milling Machine

| Number of axes |

5-axis |

|---|---|

| Axis drive |

Full high-precision servo |

| Rotation angle of the A-axis |

360 degrees |

| Rotation angle of the B-axis |

±33 degrees |

| Spindle |

860 watts – high frequency, speed up to 60,000 RPM |

| Tool changer |

Automatic air blower without the need for a compressor |

| Ambient temperature control |

Optimal operation between 10 to 35 degrees Celsius |

| Body material |

Integrated cast aluminum |

| Disk/Block dimensions |

D: 98 mm; Height: 10–30 mm / Maximum: 40 × 20 × 20 mm |

| Machinable materials |

Zirconia, wax, PMMA, PEEK, composite resin, sinterable CoCr metals |

| Machine dimensions / weight |

655 × 442 × 704 mm / 98 kilograms |

| CAM software |

UPCAM، Millbox |