UP3D P53 Dry Milling Machine

Technical and Performance Specifications

- Advanced 5-axis intelligent technology for enhanced precision

- Dry milling requiring compressor and dryer

- Fully automatic high-precision calibration

- Dual electric and mechanical sensor system for enhanced milling accuracy

- LED display for real-time milling process progress

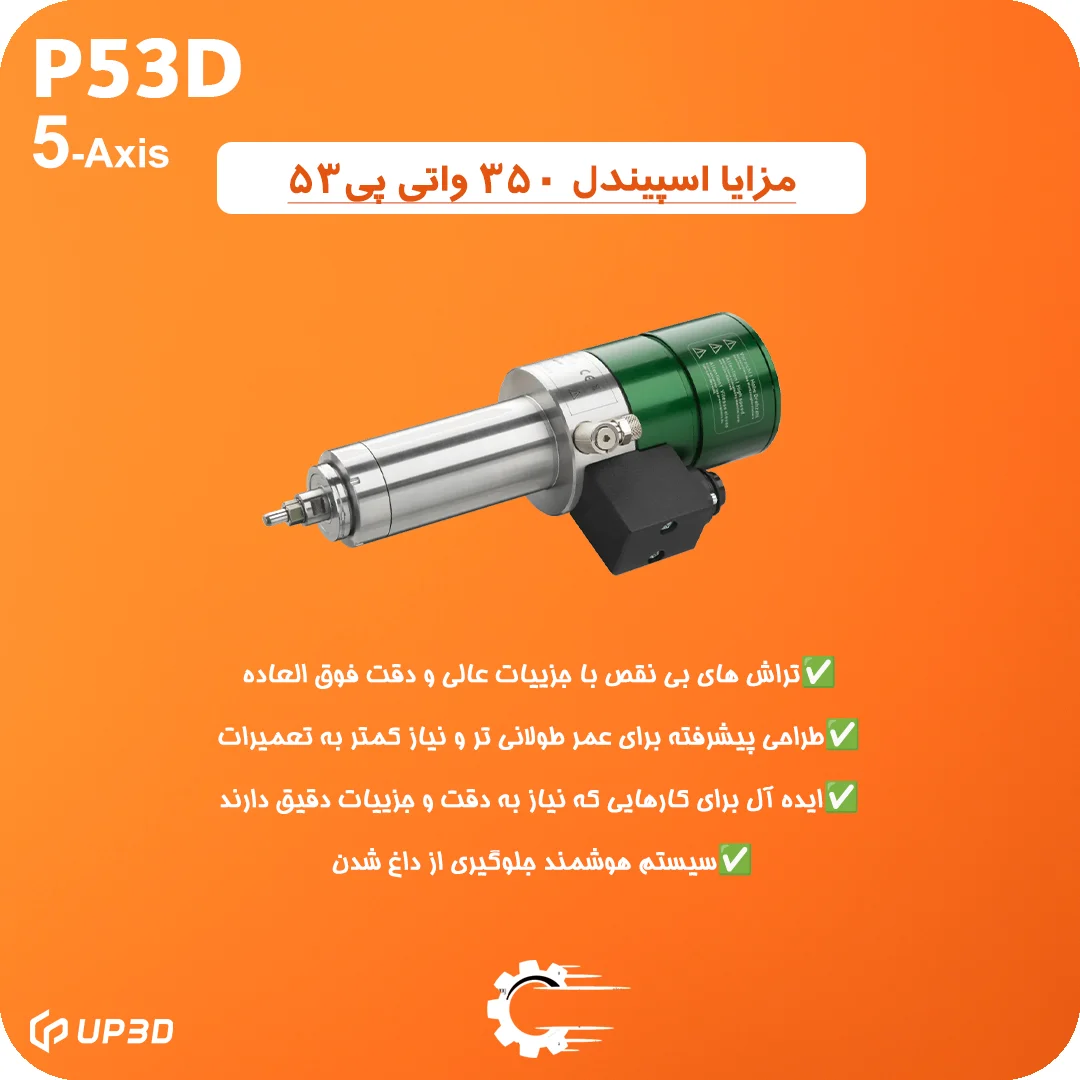

- 350W spindle for fast and precise milling with high-detail accuracy

- 11-position tool magazine offering high flexibility in tool selection

- Precision hybrid motors optimized for stable performance

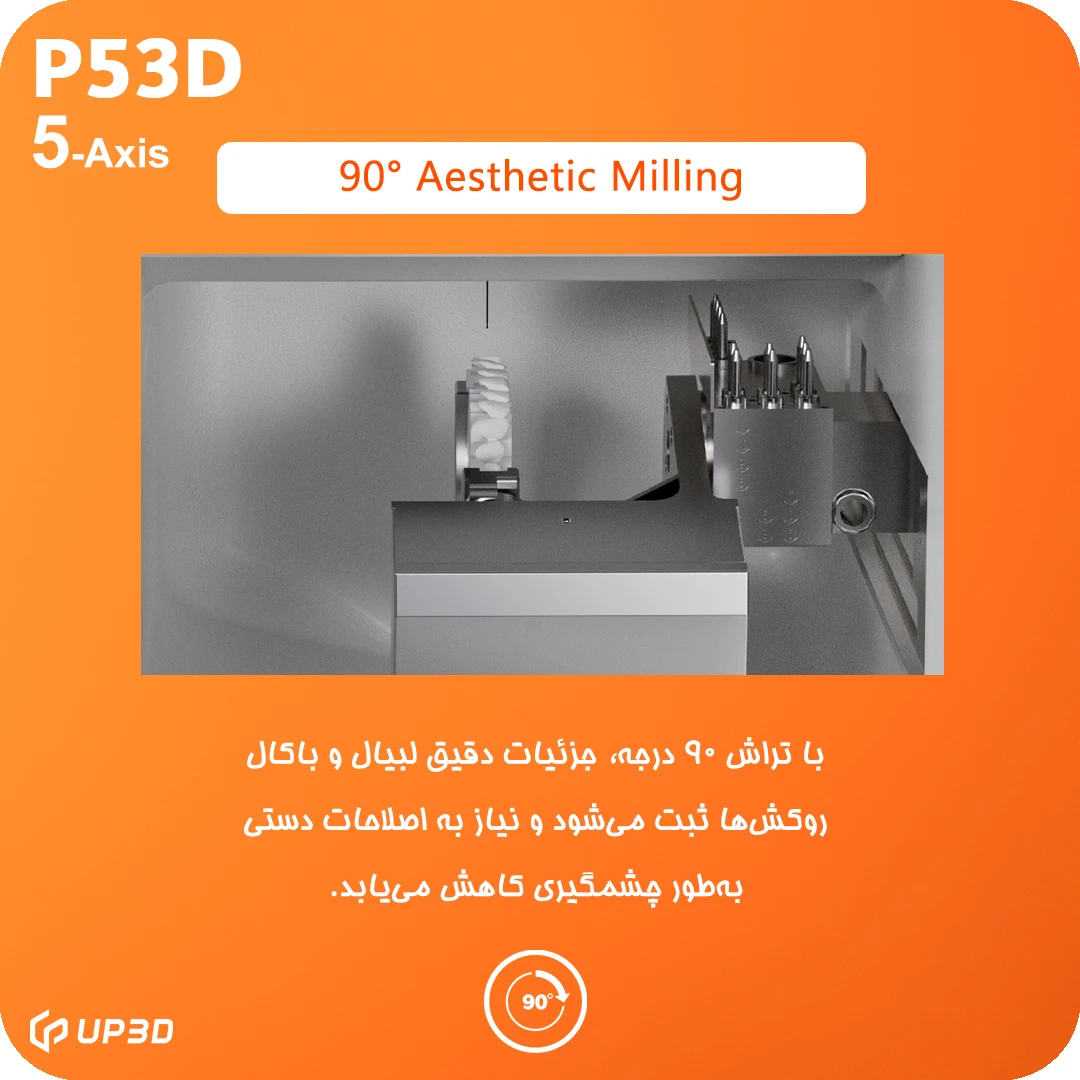

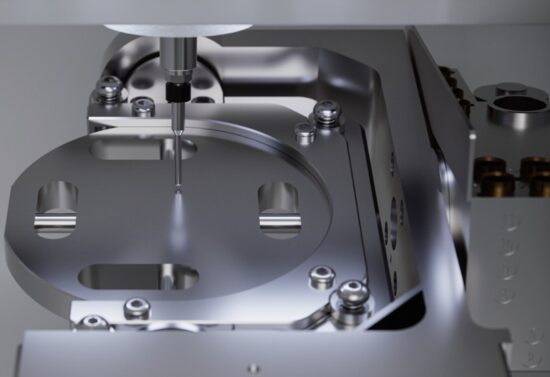

- 90-degree vertical milling capability for precise proximal area machining

- Intelligent diagnostic system for rapid detection and resolution of issues

These combined features make the UP3D P53 milling machine an ideal choice for digital dental laboratories.

1.190.000.000تومان

Introducing the UP3D P53 Milling Machine

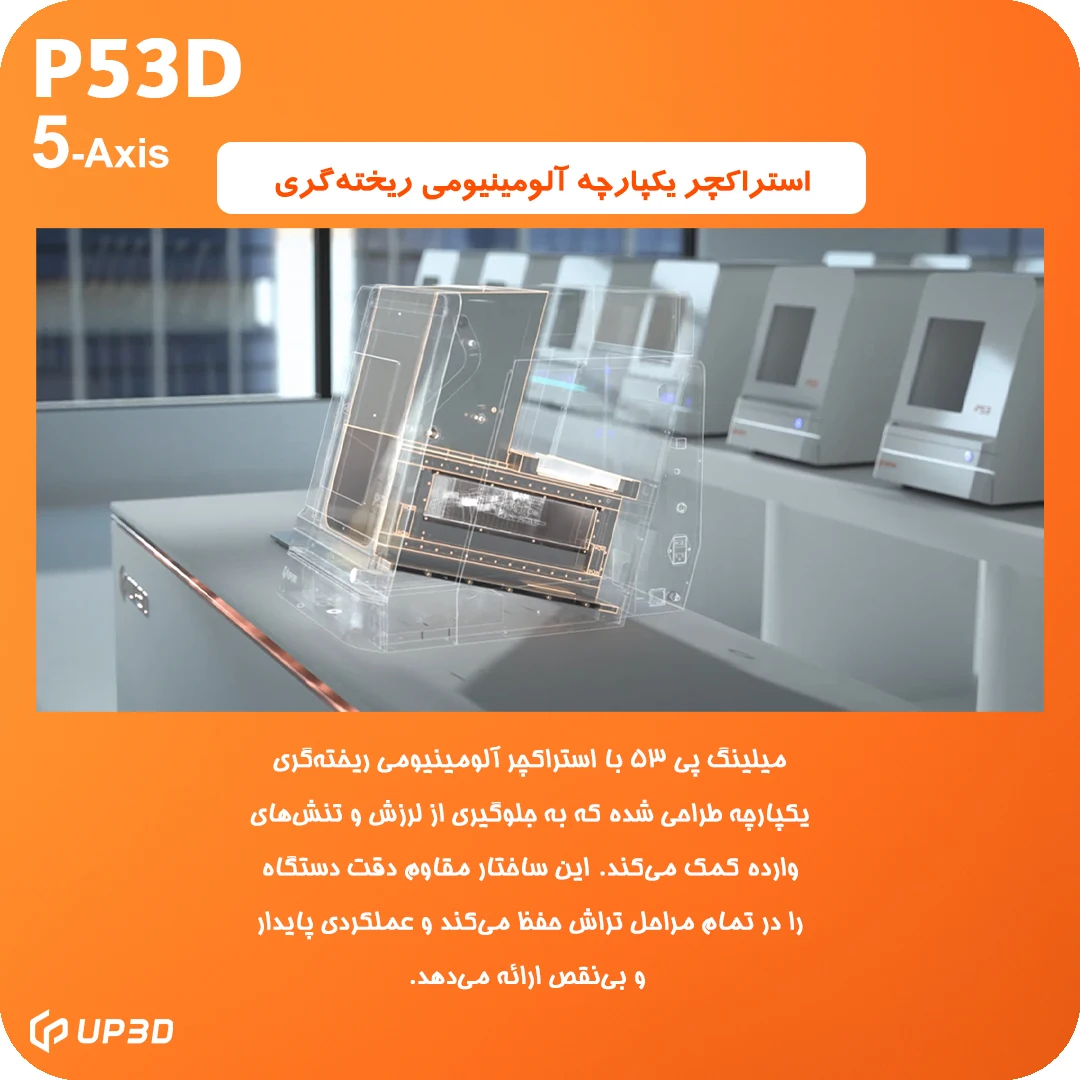

UP3D P53 Dry Milling Machine is one of the most advanced CAD/CAM systems for digital dental laboratories. Engineered with intelligent design and high-precision technologies, it is ideal for milling materials such as zirconia, PMMA, wax, and dental resins. Equipped with a 350W DECI spindle, high-precision hybrid motors, exclusive UPCNC and UPCAM software, and a vibration-resistant structure, the P53 delivers fast, accurate, and stable performance for dental labs.Key Features of the UP3D P53 Milling Machine

- 90° Vertical Milling Technology For enhanced precision in anterior regions and improved aesthetics of proximal restorations.

- Independent R&D Integrated hardware and software design by the UP3D engineering team for complete operational harmony.

- Smart Five-Point System Systems optimized for accuracy, stability, and reduction of human error during milling operations.

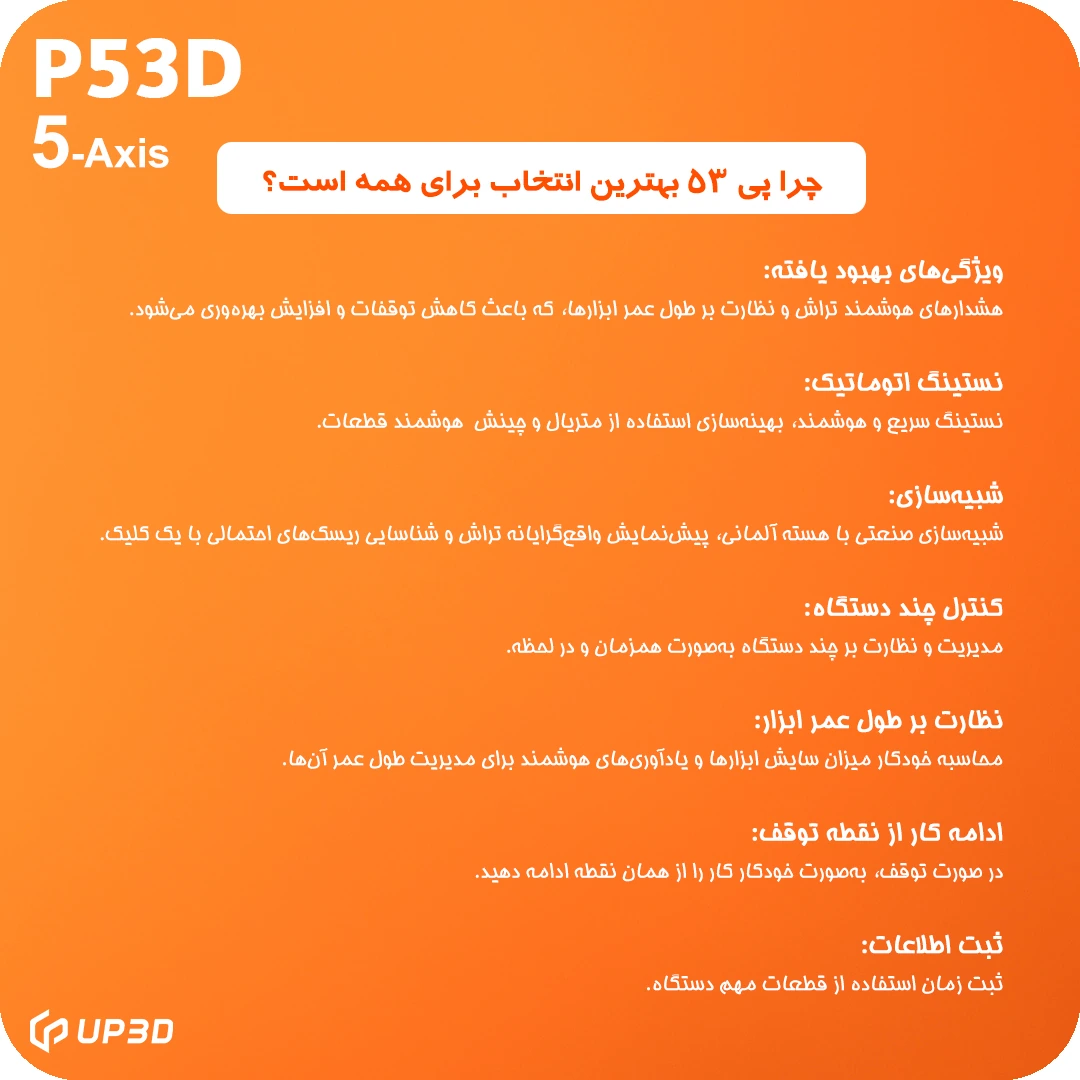

- Exclusive UPCNC Software: Simultaneous multi-machine control with a single click, enhancing milling speed and managing multiple projects concurrently.

- Half Clamp design for secure and precise holding of materials during milling operations. Reducing material waste by maximizing milling efficiency from the edges of discs or blocks.

- LED progress indicator displaying real-time milling status. Real-time milling status display, reducing the need for constant operator supervision.

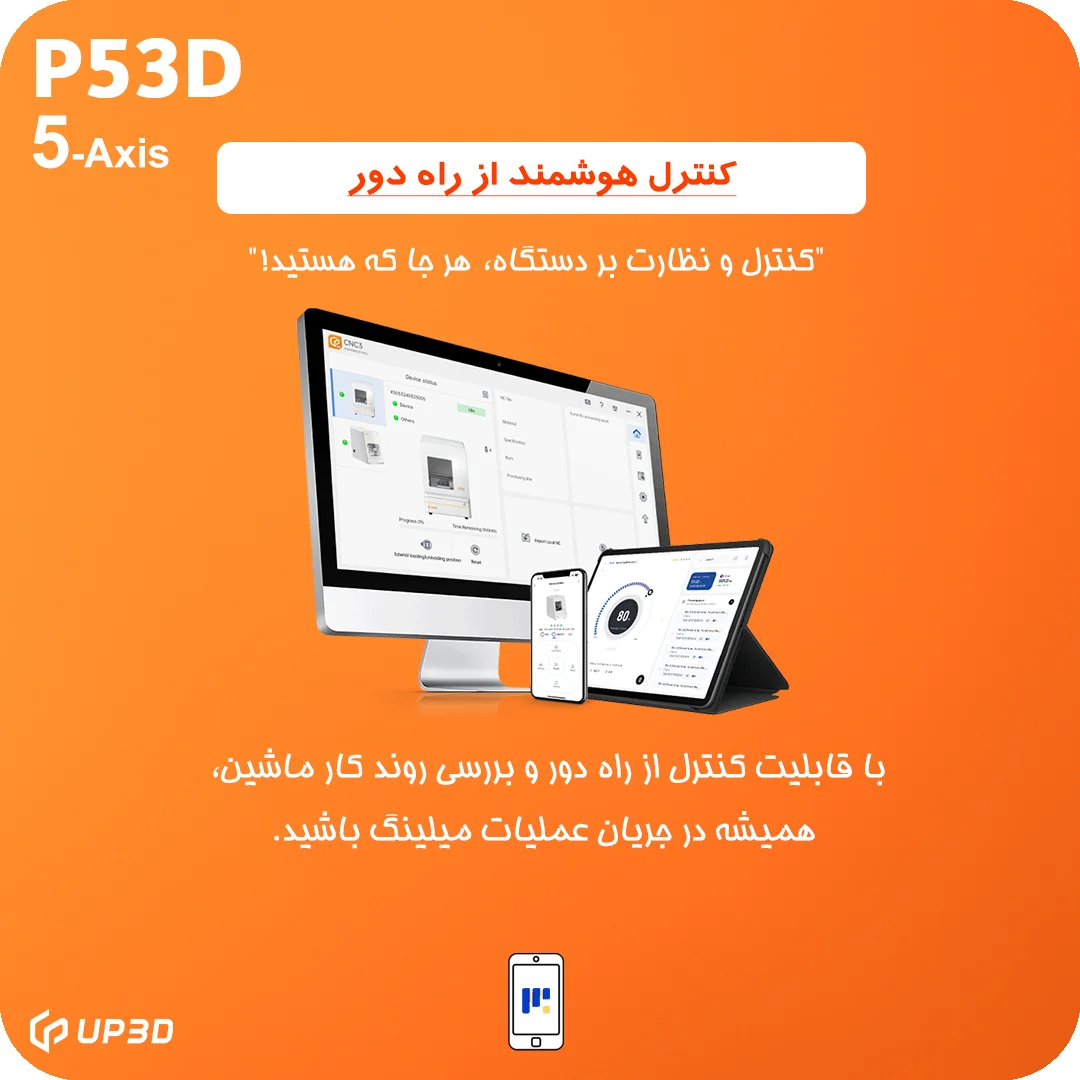

- Remote Control and Monitoring Mobile connectivity for real-time machine status monitoring and configuration.

- Intelligent Tool Life Calculation Timely alerts for tool replacement to prevent damage to sensitive materials like zirconia.

- Automatic Process Resumption If the operation is interrupted, milling resumes from the same step using an anti-repetition algorithm.

- Automatic and Precise Calibration Smart adjustment of tools and milling paths without operator intervention for maximum precision.

The UP3D P53 milling machine, with its intelligent performance and cost-effective pricing, is an exceptional choice for laboratories seeking precision, stability, and optimized management in digital milling workflows.

ZIG – Official Representative of UP3D in Iran

ZIG, as the official representative of UP3D in Iran, offers the P53 machine with full installation services, professional training, expert consultation, and technical support. To explore more products, visit the ZIG Tech section. feel free to visit or contact our team for a consultation. To view the official specifications of this device on the manufacturer’s website, click here..P53 Milling Machine – The New Generation of Digital Milling for Dental Labs

The intelligent 5-axis P53 milling machine represents a new generation of dry-milling dental equipment. Featuring an integrated structure and smart control system, it ensures smooth and precise operation. Leveraging artificial intelligence in the production of dental prosthetics, the P53 effectively supports scalable manufacturing in dental laboratories.

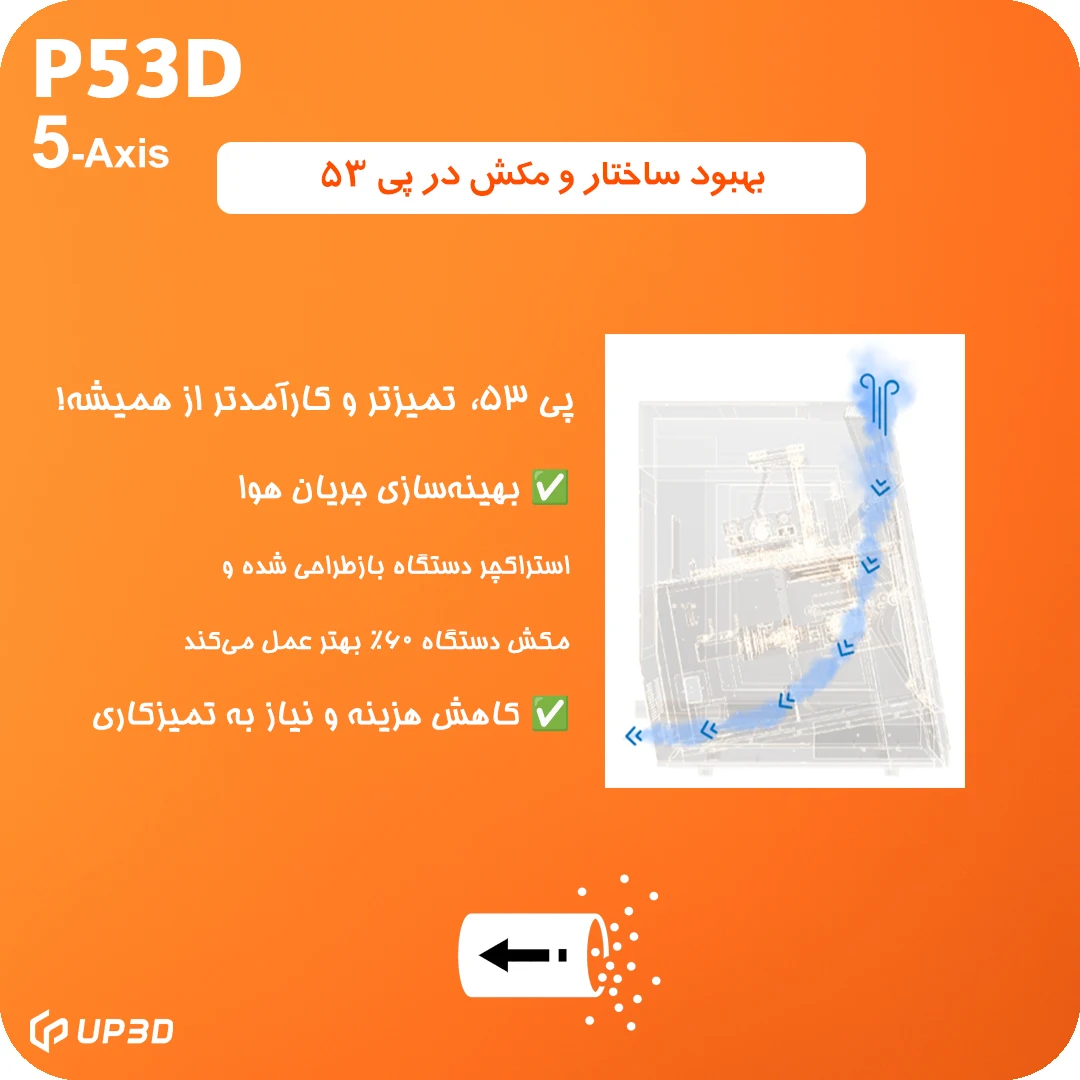

Dust-Proof Slides – Enhanced Machine Lifespan

The advanced dust-proof slide technology in the P53 dry milling machine protects internal components from environmental contaminants and prevents dust from entering sensitive systems. This innovative design significantly reduces the need for periodic maintenance and extends the machine's lifespan—resulting in a more stable, reliable, and cost-effective experience for dental laboratories.

Quick Material Change with Innovative BK-1 Clamp Design

The P53 milling machine is delivered by default with a C-clamp, but a key innovation is the quick installation capability of the BK-1 clamp within the same holder. This intelligent design allows users to switch from disk milling mode (such as zirconia discs) to block milling mode (for materials like zirconia blocks, PMMA, and resin composite) in less than 30 seconds without the need for special tools.

This feature not only saves time but also boosts laboratory efficiency by enabling the production of multiple types of dental restorations within a single work shift. Easy installation, stable design, and precise block retention are among the key advantages of the BK-1 clamp within the modular structure of the P53.

90° Vertical Milling – Precision Aesthetic Restoration

With its 5-axis technology and 90° vertical milling capability, the P53 milling machine enables precise and natural restorations. The software UPCNC allows users to define critical areas and intelligently adjust the milling type, number of tools, and operating speed. This system prevents tool collisions and enhances final precision.

Smart Remote Control with MillMind Cloud

with the cloud-based MillMind service MillMindfull management of the UP3D milling machine is easily possible via mobile or tablet. Users can monitor real-time machine status and oversee the production process remotely at any time.

This system also features smart alerts and tool life monitoring, significantly boosting lab productivity by minimizing unexpected downtimes and maximizing machine uptime.

High Precision and Stability with One-Click Smart Calibration

Performance One-Click Smart Calibration In the P53 milling machine, the calibration process is fully automated and requires no technical expertise. By precisely aligning the tool position and worktable, this feature enhances final accuracy and prevents milling errors.

The result is a significant reduction in material waste, improved restoration quality, and enhanced overall laboratory productivity. With this capability, producing high-quality dental restorations with precise repeatability becomes much easier.

✦ Resumption of Milling from Stop Point

The machine software automatically resumes milling from the last stop point, saving at least 80% of time and resources.

✦ C-Clamp Design

The innovative C-Clamp design increases the milling space in the buccal area and allows for more efficient use of material edges. This design reduces costs and enables the production of higher-quality restorations.

✦ Intelligent LED Display Bar

The external LED bar synchronizes in real-time with the milling process and displays progress. This feature eliminates the need for manual monitoring and increases production efficiency.

✦ Simultaneous Multi-Machine Control

The central CNC software enables simultaneous management of multiple machines. This feature saves workspace and boosts efficiency on a larger scale.

| Device dimensions | 570 × 490 × 600 mm |

|---|---|

| Weight | 85 kg |

| Number of axes | 5 simultaneous real axes |

| Milling type | Dry milling |

| Spindle speed | 60,000 RPM |

| Spindle power | 350 watts (DECI China) |

| Number of tools | 12 tools with automatic tool changer |

| Cooling system | Compressed air (air pressure 0.15–0.20 MPa) |

| Supported materials | Zirconia, PMMA, wax, PEEK, resins |

| CAM Software | UPCAM، Millbox |

⏳ Please wait a moment, the 3D model is loading...

Click here to view the product on the official UP3D website:

View on UP3D website🎥 Video Introduction of UP3D P53 Milling Machine

| Number of axes |

5-axis |

|---|---|

| Axis drive |

High-precision hybrid stepper motors |

| Rotation angle of the A-axis |

±30 degrees |

| Rotation angle of the B-axis |

±360 degrees |

| Spindle |

350 watts – high maneuverability, speed up to 60,000 RPM |

| Tool changer |

Automatic |

| Ambient temperature control |

Optimal operation between 10 to 35 degrees Celsius |

| Body material |

Integrated cast aluminum |

| Disk/Block dimensions |

D: 98 mm; Height: 10–30 mm / Maximum: 40 × 20 × 20 mm |

| Machinable materials |

443.5 × 718 × 628.5 mm / 87 kg |

| Machine dimensions / weight |

655 × 442 × 704 mm / 98 kilograms |

| CAM software |

UPCAM، Millbox |

| Spindle cooling system |

Requires compressor with air pressure of 0.5 MPa |

| Total power |

1.1 kilowatts |